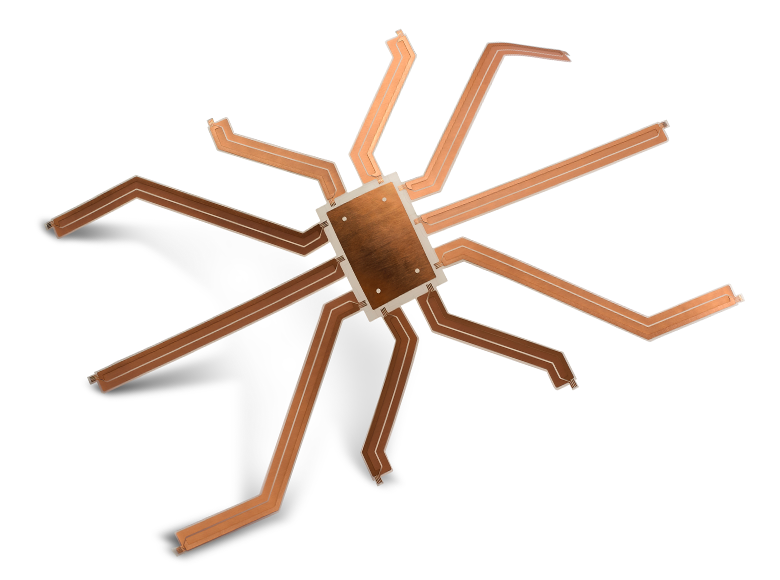

Automotive Flex Harness

Bringing Electrical Distribution Systems to the 21st Century

CelLink’s circuits provide much greater control over

power and data transmission than traditional round wire

– at 1/4th the weight and 1/10th the volume.

Circuit construction

A typical CelLink wire harness circuit construction might include:

- 75-125 µm thick flame-retardant PEN, polypropylene, or LLDPE coverlay

- 70-125 µm thick copper or tin-plated copper conductor

- 75-125 µm thick flame-retardant PEN, polypropylene, or LLDPE coverlay

For high speed data transmission, 250 µm LLDPE or polypropylene layers and 35 µm copper shield layers may be included in the circuit construction for low-loss, impedance matched signal transmission.