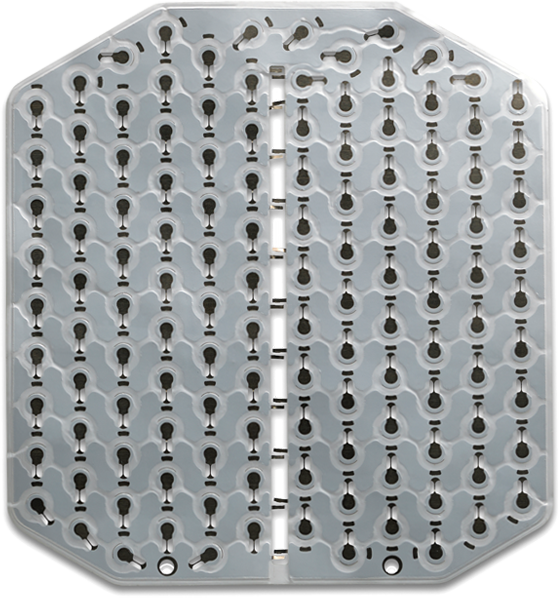

Battery Pack Interconnect

The Ultimate Pack Wiring Solution

CelLink’s high-conductance circuits integrate busing, fusing, voltage monitoring,

and temperature monitoring wiring systems into a single circuit.

Circuit construction

A typical CelLink battery circuit construction might include:

- 50-125 µm thick flame-retardant PEN coverlay or FRB paper dielectric

- 100-1000 µm thick aluminum busing conductor(s)

- 70-125um thick aluminum cell contacting layer

- 50-125 µm thick flame-retardant PEN coverlay or FRB paper (optional)